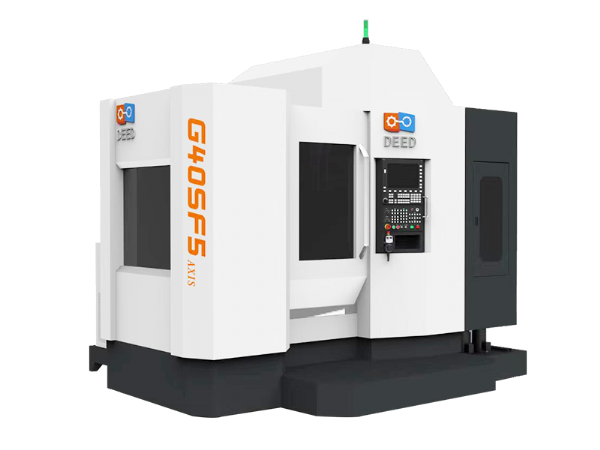

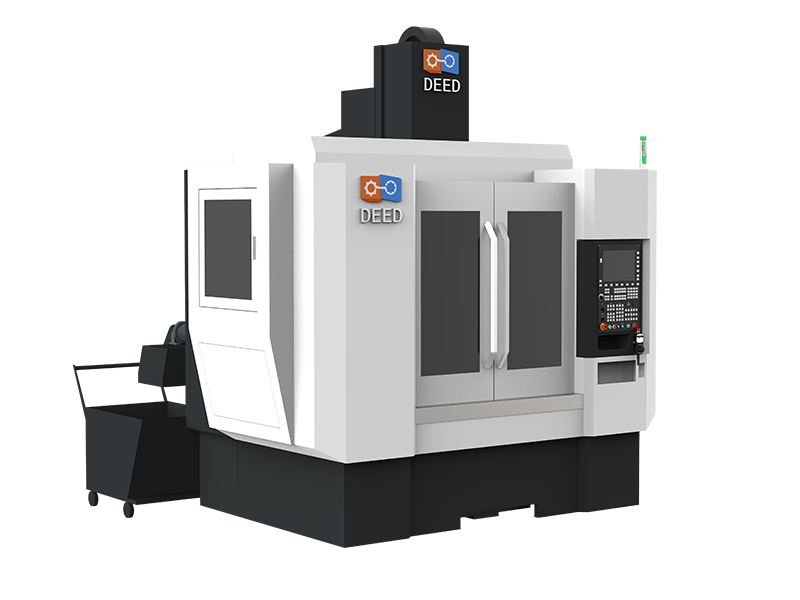

Five axis machining center

High precision; High rigidity

German technology | Made in China | New materials and processes

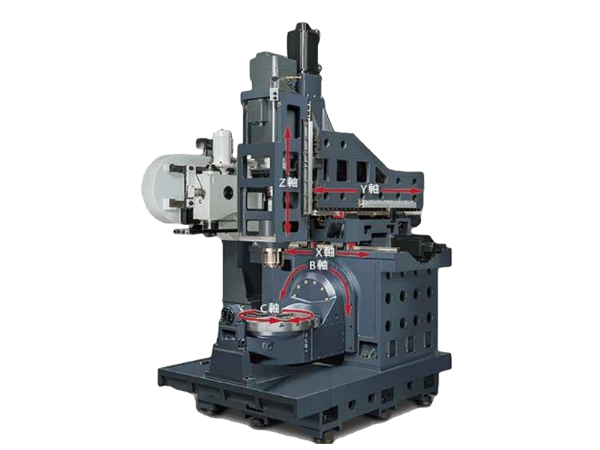

Five axis machining center

Maximum working speed of the spindle:18000r/min

Torque (rated/maximum):72N·m

Power (rated/maximum):30KW

Maximum working speed of the spindle:18000r/min

Torque (rated/maximum):95N·m

Power (rated/maximum):35KW

Maximum working speed of the spindle:18000r/min

Torque (rated/maximum):72N·m

Power (rated/maximum):30KW

This equipment is a small and medium-sized specifications vertical five axis machining center designed by a well-known machine tool design company in Europe and manufactured in China. It is a new generation of high-speed and high accuracy products with bridge structure, combined with years of machine tool design and manufacturing experience of our company and the use requirements of a large number of users. It can be widely applied to the processing of complex curved surface parts in various types of mechanical processing industries, such as blade, impeller, mold industry, etc., and can meet the needs of multi variety processing of small and medium-sized box parts and spatial curved surfaces. It is widely used in civil industry such as aerospace, mold and military enterprises.

Maximum working speed of the spindle:15000r/min

Torque (rated/maximum):52.5/105N·m

Power (rated/maximum):11/18.5KW

Maximum working speed of the spindle:15000r/min

Torque (rated/maximum):52.5/105N·m

Power (rated/maximum):11/18.5KW

Maximum working speed of the spindle:15000r/min

Torque (rated/maximum):52.5/105N·m

Power (rated/maximum):11/18.5KW

Maximum working speed of the spindle:18000r/min

Torque (rated/maximum):72N·m

Power (rated/maximum):30KW

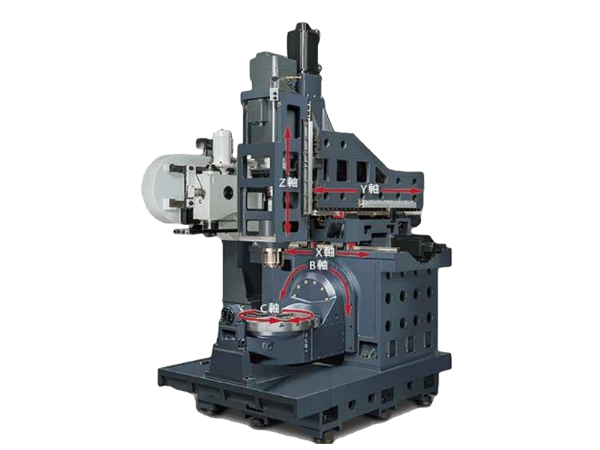

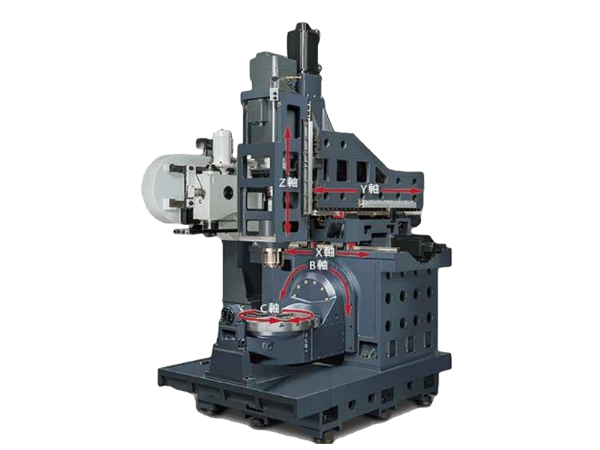

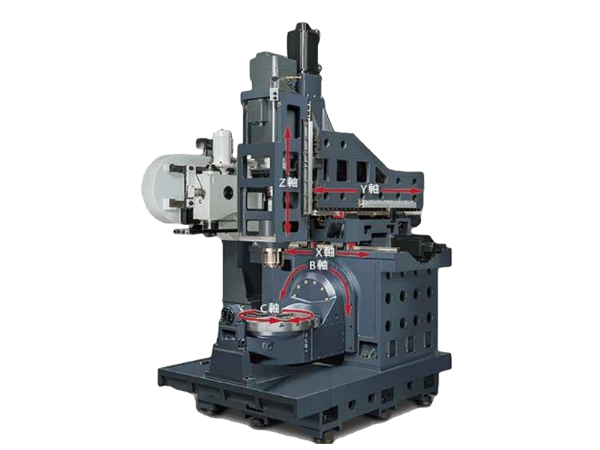

GF series vertical cradle five axis linkage machining center is a small vertical five axis linkage machining center designed by Germany and made in China. The complete machine adopts an improved high rigid gantry structure, which overcomes the instability of the traditional cross slide table.

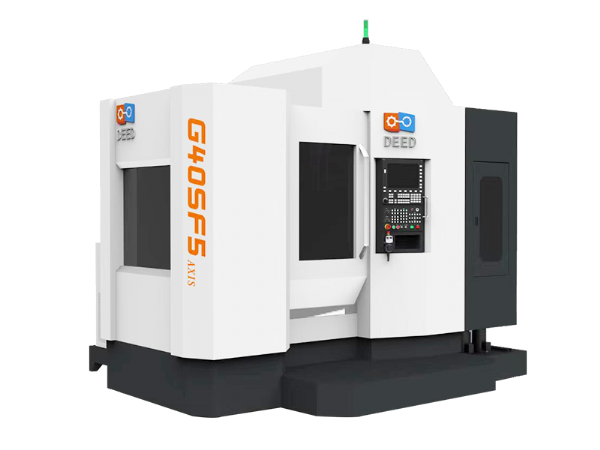

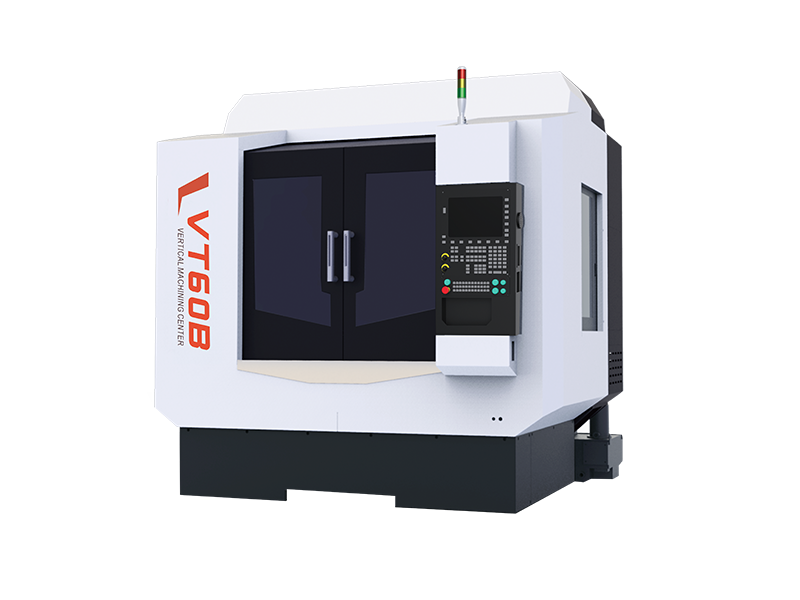

VF series vertical cradle five axis machining center is a small vertical five axis machining center designed by Germany and made in China. The complete machine adopts a movable column structure, with compact structure and small floor area. It is mainly used to process special-shaped parts, seats, shells and other parts with complex processes and high accuracy requirements. It is suitable for high accuracy processing of parts and components in the fields of mold, parts, hardware, auto parts, medical devices, cutting tools and so on.

Home

Home

Products

Products

Mod

Mod