Milling and boring machining center

High precision; High rigidity high efficiency

German technology | Made in China | New materials and processes

Milling and boring machining center

Boring shaft speed:10~1500rpm

Rated output torque of the spindle:5196/9252N·m

Spindle power:74/93KW

Boring shaft speed:10~2000rpm

Rated output torque of the spindle:3500/5254N·m

Spindle power:60/90KW

Boring shaft speed:10~1500rpm

Rated output torque of the spindle:5196/9252N·m

Spindle power:74/93KW

Maximum working speed of the spindle:10~2000r/min

Spindle output torque:3976/5065N·m

Power (rated/maximum):58/74KW

Maximum working speed of the spindle:10~2500r/min

Spindle output torque:1155/1369N·m

Power (rated/maximum):22/26KW

Maximum working speed of the spindle:10~3000r/min

Spindle output torque:1155/1369N·m

Power (rated/maximum):22/26KW

Maximum working speed of the spindle:10~2500r/min

Spindle output torque:2500/3020N·m

Power (rated/maximum):37/45KW

Maximum working speed of the spindle:10~3000r/min

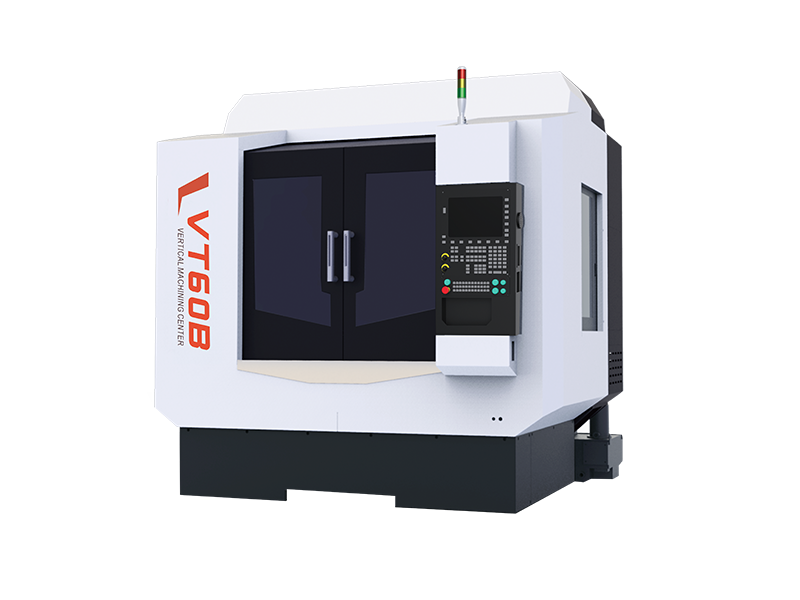

Torque (rated/maximum):168/305N·m

Power (rated/maximum):1155/1369KW

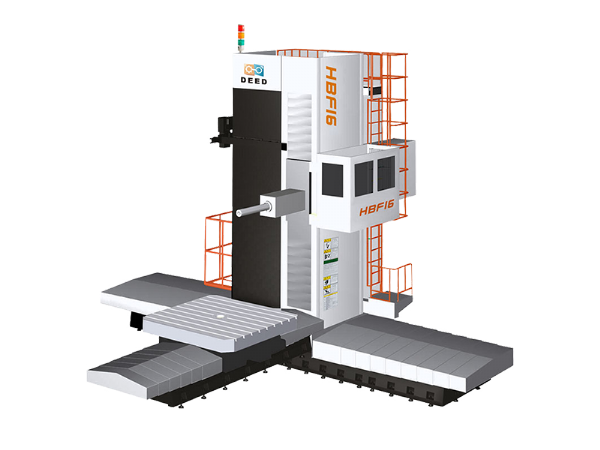

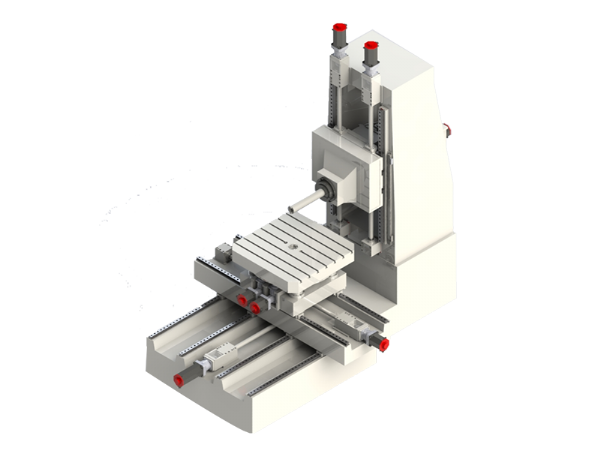

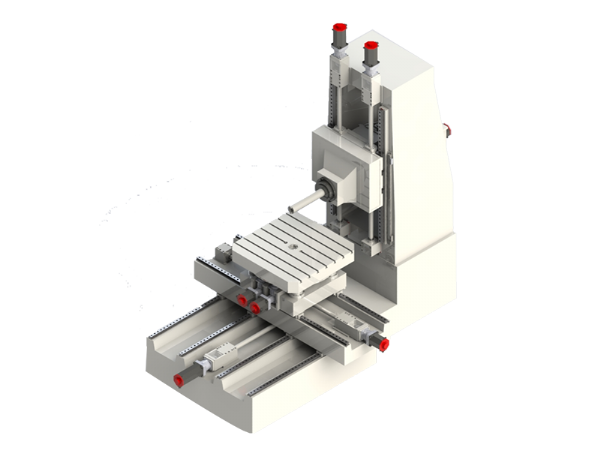

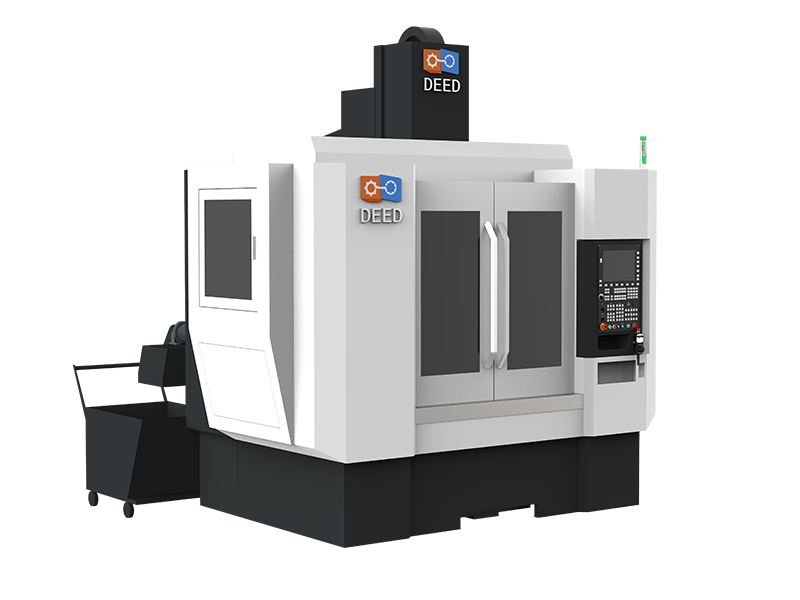

HBC series horizontal milling and boring machining center. This series of machine tools is a horizontal milling and boring machining center. The column is fixed to the bed, with a cross slide structure. The machine range moves left and right (x axis), and the main shaft box moves up and down on the column (Y axis)

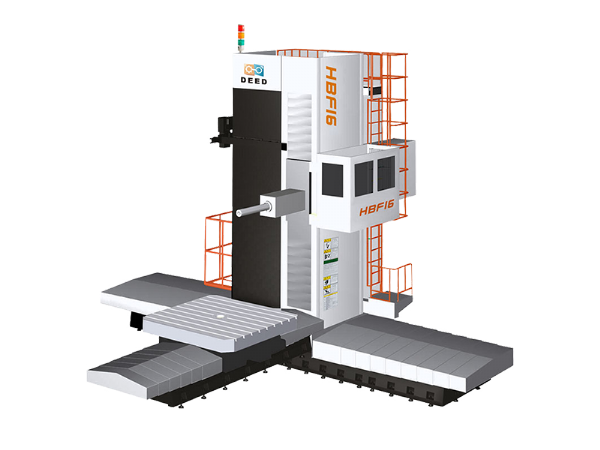

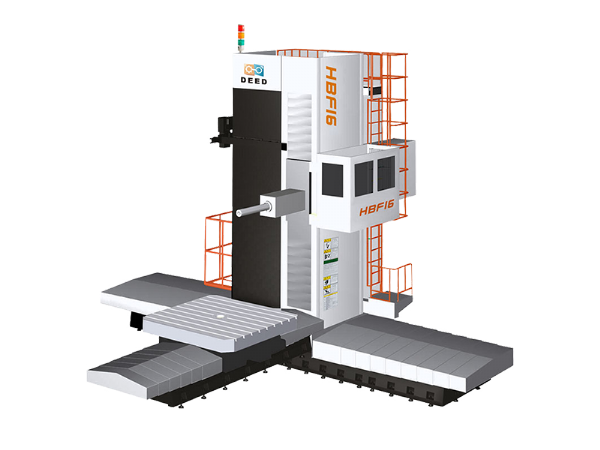

This series of machine tools is a planer type milling and boring machine center The workbench moves left and right on the front bed (x-axis), the spindle box moves up and down on the column (Y-axis), the column moves back and forth on the rear bed (Z-axis), the boring axis moves back and forth (W-axis), and the workbench rotation (b-axis) The front and rear beds are made of new mineral materials, which provide more stability

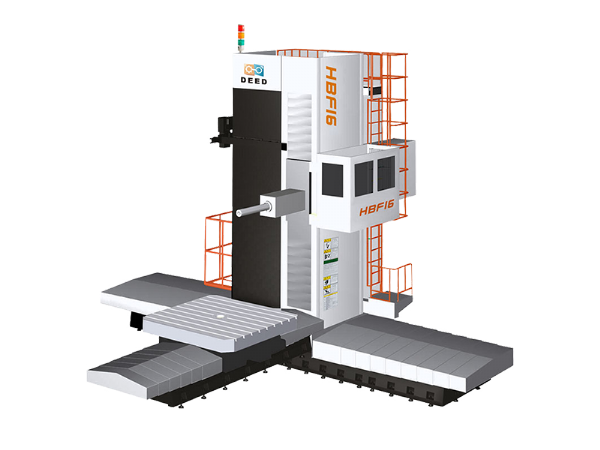

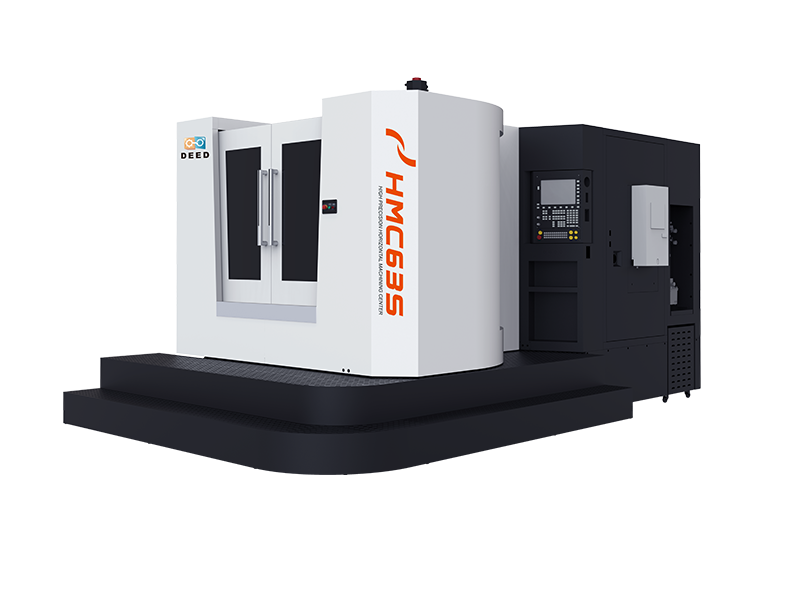

This series of machine tools are movable columns and main shaft box (main shaft diameter φ More than 200 are side hung), RAM mobile layout, and equipped with CNC turntable (or floor platform). The x-axis of the machine tool is synchronously driven by two servo motors, precision reducers and high accuracy gears and racks, while other axes are driven by servo motors, precision reducers and high accuracy ball screw pairs.

Home

Home

Products

Products

Mod

Mod