Wheel hub special machine

Good vibration absorption, stability, and strong rigidity

German technology | Made in China | New materials and processes

Wheel hub special machine

Maximum working speed of the spindle:2500rpm

Torque (rated/maximum):55/115N·m

Power (rated/maximum):37/45KW

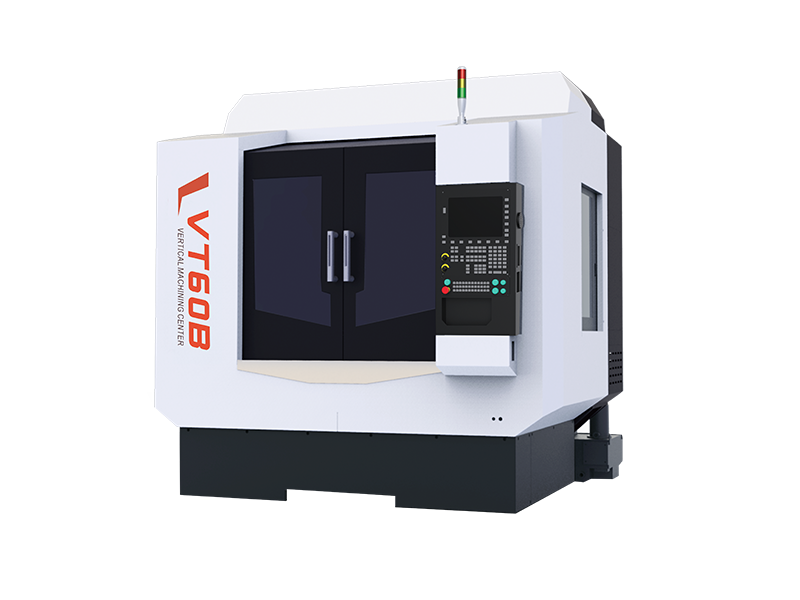

The vertical wheel hub turning center is mainly used for rough and fine turning of common 14-26 inch carburetor wheel hubs, with advantages such as high efficiency, uniform patterns, and stable performance. The machine tool adopts a vertical four hard rail structure, with a compact structure and a user-friendly operation layout design. The sheet metal adopts a fully enclosed protective structure, with good chip drainage and leak prevention effect.

Maximum speed:2500r/min

Fast moving speed:20/20m/min

Main motor power:30/37rpm

Maximum speed:2500r/min

Fast moving speed:20/20m/min

Main motor power:30/37rpm

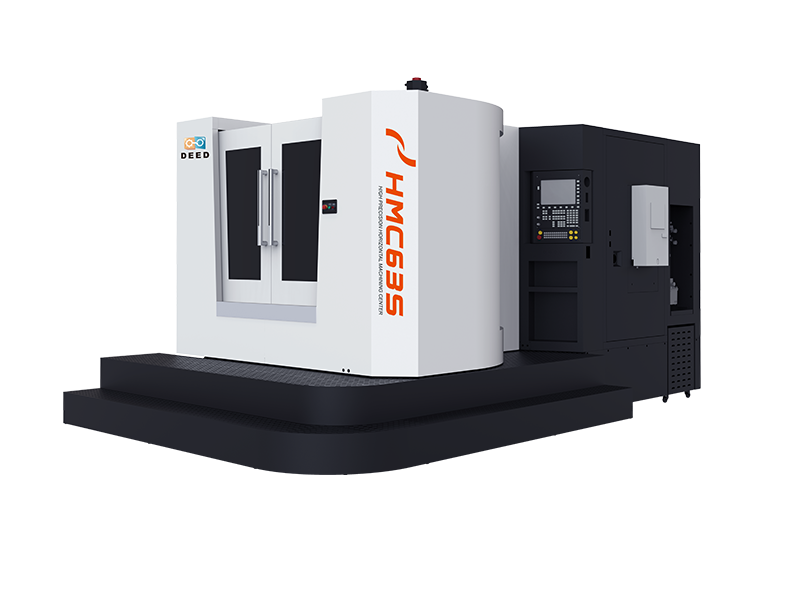

Maximum working speed of the spindle:15000r/min

Torque (rated/maximum):55/115N·m

Power (rated/maximum):37/45KW

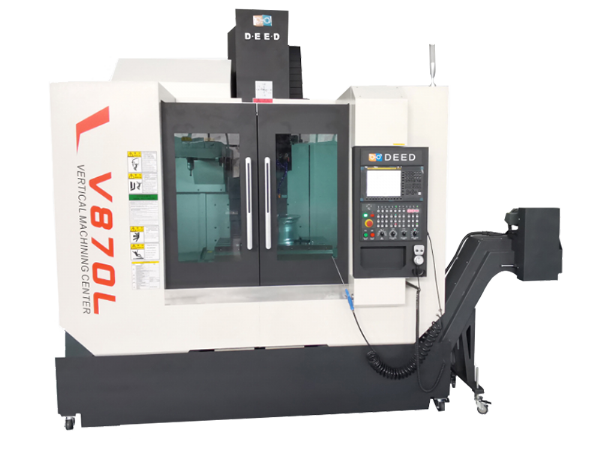

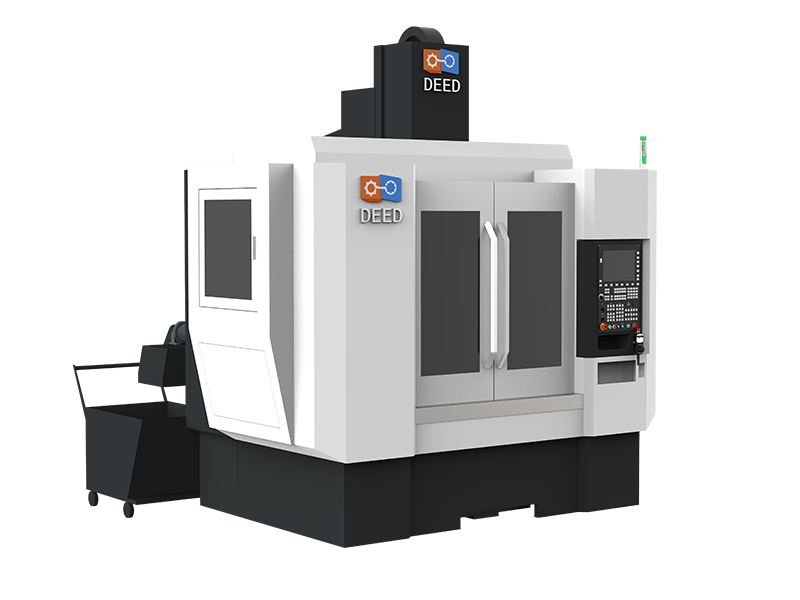

The vertical machining center adopts a cross sliding table moving structure, and the guide rail adopts a linear rolling guide rail, which is mainly used for the processing of various small and medium-sized complex parts. It can complete milling, drilling, expanding, boring, tapping, contour milling and other processing under one-time clamping, and is suitable for the processing of automobile hub;

The mineral casting bed has good vibration absorption performance; Improving tool life, improving machining surface quality, good thermal stability, and strong rigidity; The 45 ° inclination angle machining has stronger rigidity, which is conducive to chip falling, and it is convenient to remove chips when combined with Chip conveyor; High hardness slide rail, rail surface quenching hardness HRC52 °~61 °, high rail accuracy retention, wear resistance, and long service life.

Home

Home

Products

Products

Mod

Mod