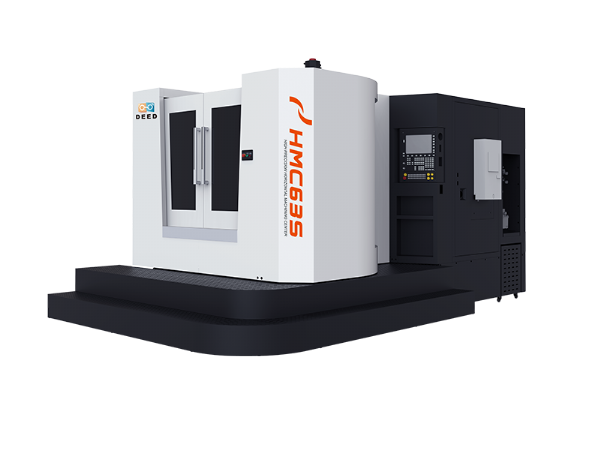

machining center

High rigidity and precision

German technology | Made in China | New materials and processes

machining center

Maximum working speed of the spindle:6000r/min

Torque (rated/maximum):143/236N·m

Power (rated/maximum):15/18.5KW

Maximum working speed of the spindle:6000r/min

Torque (rated/maximum):143/236N·m

Power (rated/maximum):15/18.5KW

Maximum working speed of the spindle:6000r/min

Torque (rated/maximum):143/236N·m

Power (rated/maximum):15/18.5KW

Maximum working speed of the spindle:6000r/min

Torque (rated/maximum):143/236N·m

Power (rated/maximum):15/18.5KW

Maximum working speed of the spindle:6000r/min

Torque (rated/maximum):649/770N·m

Power (rated/maximum):18.5/22KW

Maximum working speed of the spindle:6000r/min

Torque (rated/maximum):649/770N·m

Power (rated/maximum):18.5/22KW

Maximum working speed of the spindle:6000r/min

Torque (rated/maximum):649/770N·m

Power (rated/maximum):18.5/22KW

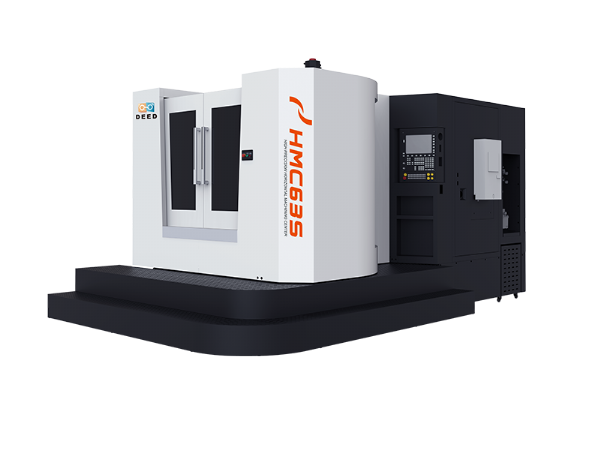

HMC single station horizontal machine center, with inverted T-shaped overall bed structure and door type double wall column structure design, has strong structural rigidity, large trip and high accuracy. It is suitable for various heavy cutting and high accuracy machining fields, and has a variety of processing functions such as milling, boring, drilling (drilling, expanding, reaming), tapping and so on.

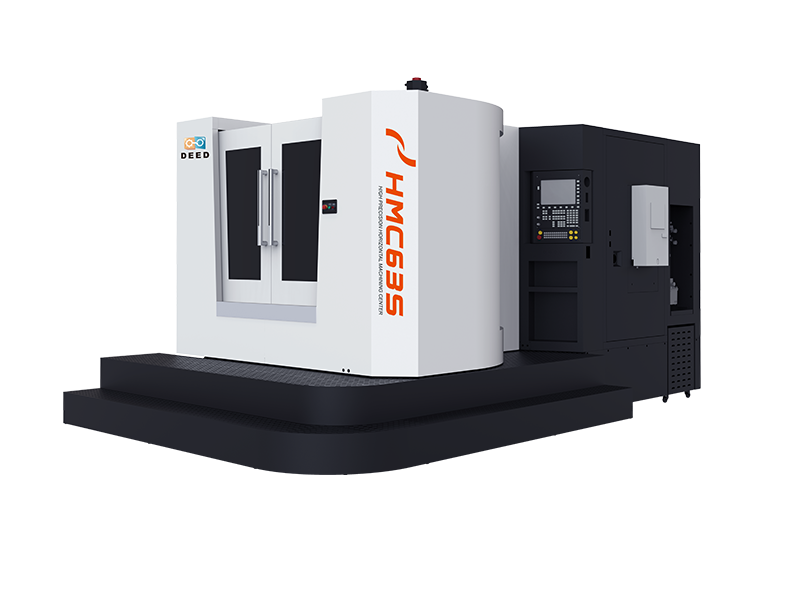

The HMC dual station horizontal machining center adopts an inverted T-shaped integral bed structure and a door shaped double wall column structure design. It has strong structural rigidity, large stroke, and high accuracy, suitable for various heavy cutting and high accuracy mechanical processing fields. It has multiple processing functions such as milling, boring, drilling (drilling, expanding, hinge), threading, spot milling, etc., ensuring efficiency and high accuracy for the processing needs of single pieces or small and medium-sized batch products.

Home

Home

Products

Products

Mod

Mod