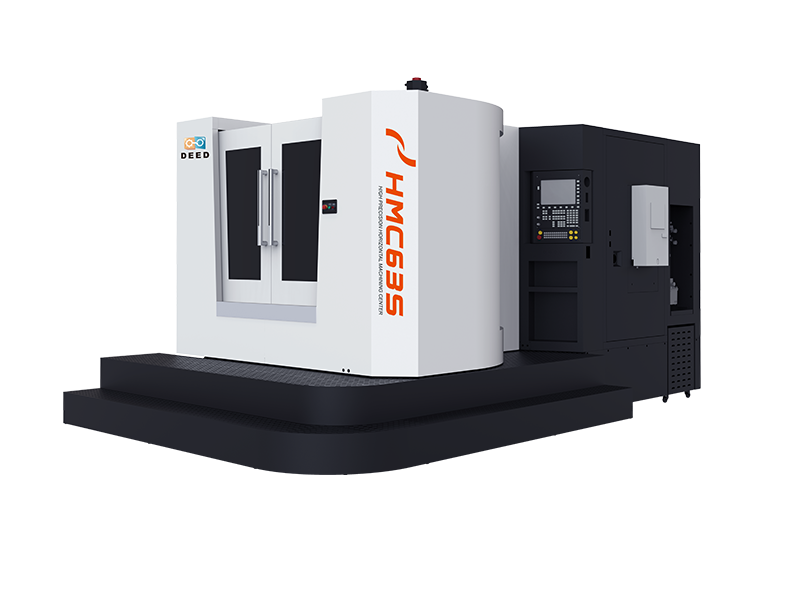

HBC series horizontal milling and boring machining center

Product features

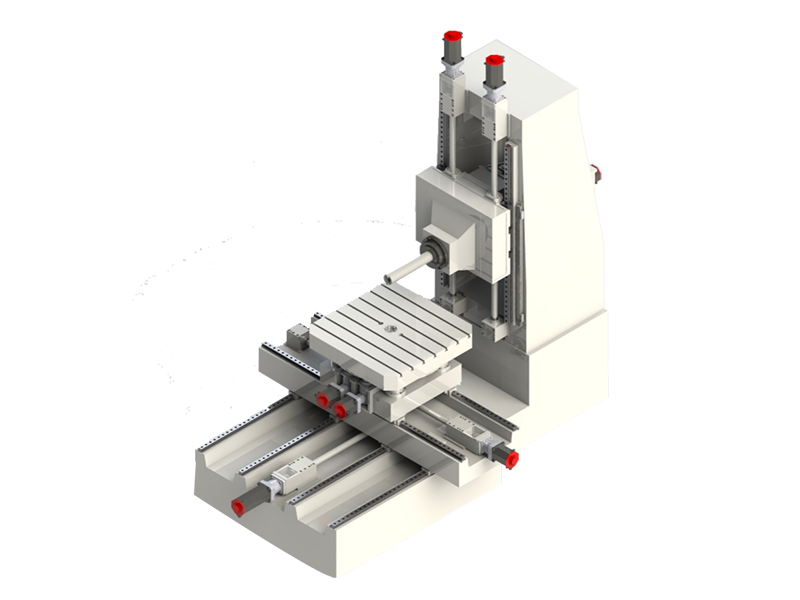

This series of machine tools is a horizontal milling and boring machining center, with a column fixed to the bed and a cross slide structure. The workbench moves left and right (X-axis), the spindle box moves up and down on the column (Y-axis), the workbench moves forward and backward (Z-axis), the boring axis moves forward and backward (W-axis), and the workbench rotates (B-axis). The bed is made of new mineral materials, which provide more stable accuracy.Configuration

Technical parameters of HBC series horizontal milling and boring machining centers

Project | Unit | HBC1116 | HBC1320 | |

Machine range | Horizontal (X-axis) stroke of workbench | mm | 1600 | 2000 |

Vertical (Y-axis) travel of spindle box | mm | 1200 | 1500 | |

Vertical (Z-axis) stroke of the column | mm | 1200 | 1500 | |

Boring axis (W-axis) stroke | mm | 550 | 700 | |

Workbench rotation (B-axis) positioning stroke 2 | Automatic continuous 360 ° | |||

Distance range from boring axis center to worktable | mm | 0~1200 | 0~1500 | |

The range of distance between the end face of the boring shaft and the center of the workbench | mm | -20~1730 | -20~2180 | |

Staging | Workbench size | mm | 1250×1250 | 1400×1600 |

T-shaped groove (size x quantity x spacing) | mm | 22×7×160 | 22×7×180 | |

Minimum angle of workbench rotation | ° | 0.001(Arbitrary division) | ||

kg | 6000 | |||

Main shaft | spindle taper/Specification of pulling nails/tool handles | 7:24(ISO BT50)/ BT50-45°/ BT50 | ||

Boring spindle diameter | mm | φ110 | φ130 | |

Spindle power(S1/S6) | Kw | 22/26 | ||

Boring shaft speed | rpm | 10~3000 | 10~2500 | |

Rated output torque of the spindle(S1/S6) | Nm | 1155/1369 | ||

Feed | Feed rate X/Y/Z/W axis | mm/min | 2~6000 | |

Maximum rotation speed of the workbench | rpm | 5 | ||

Fast moving speed | m/min | X: 15 Y:15 Z:15 W:5 | ||

accuracy | Positioning accuracy(semi-closed loop/closed loop) | mm | X/Y/Z 0.025/0.015 | W(semi-closed loop) 0.025 |

repeatPositioning accuracy(semi-closed loop/closed loop) | mm | X/Y/Z 0.015/0.008 | W(semi-closed loop) 0.02 | |

Workbench rotation (B-axis)Positioning accuracy | 12" | |||

Workbench rotation (B-axis)repeatPositioning accuracy | 6" | |||

complete machine | power capacity | KVA | 60 | 80 |

Machine weight | kg | 25000 | 30000 | |

Machine tool footprint (length x width x height) | m | 6×7×4.8 | 7×8×5.5 | |

Video

Application

Standard Configuration

CNC systemSiemens

spindle bearing

Turntable bearing

Rotary table circular grating

linear guideway

Ball screw

Screw support bearing

Screw nut

planetary reducer

Dual speed gearbox

Air source filtration and purification device

Cable drag chain

Hydraulic station

Main electrical components

Which option is most suitable for you?

Jifu knife magazine

Li Jingxiang Center Flushing

Three-axis grating

Knife alignment instrument

Workpiece measurement

Location:

Location:

Home

Home

Products

Products

Mod

Mod